Scroll to

The Group actively takes responsibility for environmental protection and strives to minimise the impact of business operations on the environment through energy-saving and emission reduction practices as well as raising the environmental awareness of our employees.

The Group's primary air pollutant emissions come from the use of boilers in the operating management business and the use of automobiles in subsidiaries of various businesses. Huanggu Thermoelectricity strictly complies with the requirements of the 14th Five-Year Plan for Urban Residential Heating Supply of Shenyang and has completed ultra-low emissions retrofits. Our measures include:

The Group's non-hazardous waste mainly includes construction waste from facade contracting engineering business, fly ash, slag, and desulphurised gypsum from Huanggu Thermoelectricity under the investing and operating business and other waste from the production process, as well as general office and domestic waste. The hazardous waste mainly includes electronic products, waste lamps, waste batteries, waste cartridges, used oil from the manufacturing and office processes, waste vanadium-titanium-based catalysts produced by the flue gas denitrification system and chemical waste generated from facade contracting engineering projects. The Group strictly manages waste, and subsidiaries have established policies tailored to their specific business characteristics to minimise the adverse environmental impact of their operations.

To reduce the emission of non-hazardous waste, the Group has implemented various measures, including reducing paper consumption, promoting the online document management, e-stamping and electronic file library system, and encouraging staff to sort and recycle.

| Through these steps, the Group has successfully obtained the Wastewi$e Certificate (Good Level) certified by the Hong Kong Green Organization. |  |

The Group's major wastewater includes the flue gas desulphurisation wastewater and domestic sewage from the investing and operating management business. In addition to strictly comply with laws and regulations such as "Integrated Wastewater Discharge Standard", the Group also closely monitors sewage discharge through the following measures:

Water resource management is a priority for the Group. We not only advance the standardised management of water usage but also optimise equipment through technological innovation to improve circulating water utilisation rates.

At operating level, Huanggu Thermoelectricity – the Group's primary water-consuming subsidiary – has implemented multiple water conservation measures with significant results. The facility has completed its Phase One of its secondary reclaimed water renovation project within the plant and implemented comprehensive upgrades to its steam-based heating system during the 2024 heating season, achieving the transition to recirculated water heating supply. Huanggu Thermoelectricity's steam-water loss rate during heating season now meets industry benchmark standards.

At corporate level, the Group mandates all subsidiaries to rigorously enhance water management efficiency. This includes stringent monitoring of consumption data and preventing unaccounted water losses to eliminate wastage at source.

The Group regards energy management as a core strategy for enhancing operational efficiency and reducing climate impact. Our Environmental Policy explicitly mandates that subsidiaries regularly review and monitor energy consumption, set specific targets, and integrate energy-saving and emission-reduction measures into daily operations.

At operating level, we are committed to employing cutting-edge technologies, high-efficiency equipment, and precision systems to achieve energy benefits, while continuously enhancing energy utilisation efficiency through comprehensive building practices.

Across the value chain, we persistently advance energy efficiency optimisation throughout our business upstream and downstream, actively promoting the adoption of renewable energy products.

We continue to explore innovative technologies for energy conservation and environmental protection in heating systems. We have implemented a retrofit of heating unit circulating water systems, which is expected to save 12,000 tons of standard coal, while reducing carbon dioxide emissions by 31,000 tons, sulfur dioxide emissions by 102 tons, and nitrogen oxide emissions by 89 tons each year. At the same time, we are advancing a lithium bromide circulating water waste heat recovery project, projected to save the equivalent of 6,240 tons of standard coal and 65,000 tons of water annually, while reducing carbon dioxide emissions by 16,000 tons, sulfur dioxide emissions by 53 tons, and nitrogen oxide emissions by 46 tons.

In addition, in 2024 we carried out ultra-low emission retrofits of boilers for dust removal, desulfurization, and denitrification, further optimizing the energy structure, reducing air pollutant emissions, and contributing to the achievement of low-carbon and environmentally sustainable development goals.

| Boiler Combustion System Optimisation | Energy-Efficient Transformer And Converter Upgrade | Implementation Of Retrofitting Project Of Boiler ACS System | Plan Of Launching Intelligent Regulation And Control Of Heat Pipe Network, Effectively Regulating The Heating Temperature Of Users | Innovative Technologies For Energy-Efficient And Environmentally Friendly Heating Systems | Retrofitting Project Of Low-Temperature Heating Grids |

|---|---|---|---|---|---|

| In 2024, Huanggu Thermoelectricity continued to focus on waste heat recovery from its heating units by upgrading two units to circulating water heating systems. It is estimated that each heating season will recover 300,000 GJ of residual heat, saving approximately 12,000 tons of standard coal and reducing carbon dioxide emissions by 31,000 tons. | In 2023, 13 high energy-consuming transformers and 21 convertors were replaced, which is estimated to save 194,100 kWh and 366,800 kWh of electricity per year respectively. | In 2022, after the completion of the ACS system retrofitting of boilers 6 and 7 in the factory, 4% of coal and 2% of the electricity were saved. On average, 942 tonnes of standard coal can be saved per one heating season. | After a trial lasting almost two months in 2021, the network achieved prominent results in saving energy, reducing consumption, and enhancing heat supply quality. In 2022, the technical transformation of hydraulic balance of secondary network covered an area of 1.6 million square meters, thus realizing energy saving and consumption reduction through raising the heat supply efficiency of heat exchange stations and cutting heating consumption and electricity consumption by 2-4.5% and 3-10% respectively. In 2023, 1.5 million square meters of secondary network were further upgraded. | In 2014, Huanggu Thermoelectricity implemented a contract energy management model to upgrade the unit’s circulating water system by installing two lithium bromide absorption heat pump units, each with a heating capacity of 19.15 MW. The system recovers waste heat from the unit’s circulating water, capturing an average of 160,000 GJ of residual heat per heating season, with an estimated savings of approximately 6,240 tons of standard coal. | As early as 1997, Huanggu Thermoelectricity took the lead in retrofitting the water circulation heating, which could offer water circulation heating in winter, and has achieved a low-temperature network heating supply of 302,300 GJ in 2022. On average, 300,000 GJ of residual heat are recovered per heating season, with an estimated average annual saving of 12,000 tonnes of standard coal. |

To further enhance energy efficiency, Huanggu Thermoelectricity continuously refines its Compendium of Management Systems and has established an Energy Conservation and Consumption Reduction Assessment Mechanism based on the actual conditions of its heating department. The mechanism incorporates key performance indicators such as heat, electricity and water consumption during the heating seasons into the assessment mechanism so as to achieve more profound energy conservation and emission reduction.

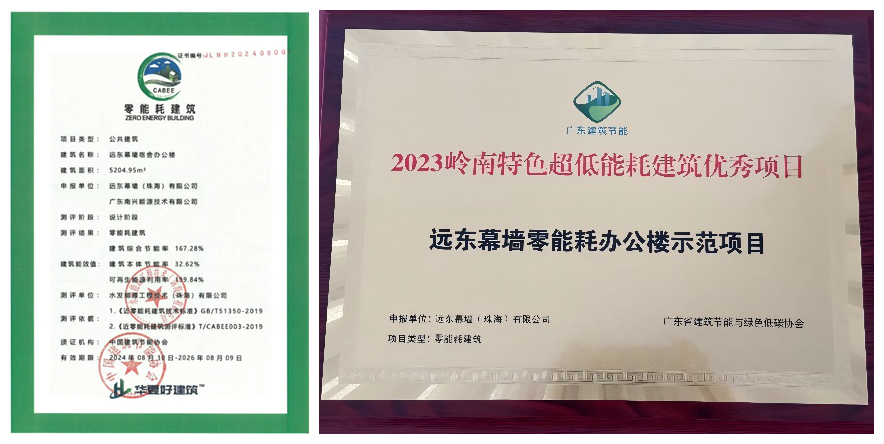

The Group's business philosophy of "Practicing diligence and thrift, Operating the enterprise frugally" is embedded in the corporate culture and applying it to the design and construction of the office environment. The Group acknowledges the importance of green office practices for sustainable development and has continually invested in creating a comfortable, low-carbon, and environmental-friendly working environment.

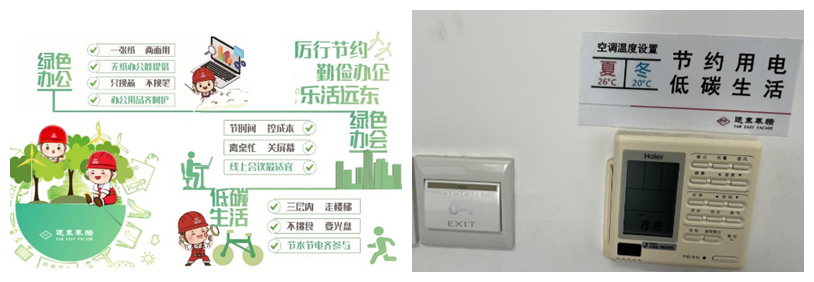

To achieve this goal, the Group promotes a green and low-carbon lifestyle among its staff through the "Green Office Environmental Proposal" and "Green Office Guidelines". The Group also monitors energy and resource usage in the office area and implements measures such as the "lights out when people leave" principle and centralised control of power supply to maximise resource and energy efficiency.

The Group was awarded the "Green Office" and "Eco-Healthy Workplace" labels from the World Green Organization for consecutive years

Save environment posters and environmental conservation signs are posted throughout the office to promote green office practices

The Group advocates instilling the concept of green office practices from the onboarding of new employees. During induction training, we emphasize the importance of creating a sustainable working environment and require employees to adopt paperless working habits in their daily work to minimise waste generation.

China Overseas Supervision "Earth Hour" Event

China Overseas Supervision proactively responded to the call for environmental protection and successfully hosted the "Earth Hour" online charity step donation event. This initiative not only encouraged employees to switch off non-essential lights during the specified time but also motivated them to connect with nature by participating in charitable initiatives through walking. Each step taken by the employees was converted into charity funds provided by China Overseas Supervision, ultimately contributing to the "Blue Defenders" environmental project. Through this activity, the concept of low-carbon environmental protection has been deeply rooted in the hearts of the employees, demonstrating our determination to contribute to the ecological environment and collectively protect our precious natural assets.

The Group combines environmental education with practical experiences in nature. Activity locations are carefully selected for their beautiful natural landscapes, allowing employees to appreciate the beauty of nature while deeply understanding the urgency of ecological protection.

To actively promote the environmental conservation concepts of waste recycling and reuse, and to rigorously reduce resource waste, the Group has arranged for professional third-party recyclers to visit our office locations, launched the "Barter for Green" environmental conservation recycling Campaign aimed at enhancing employees' participation in environmental initiatives.